Submitted by Jenny Molloy on Mon, 21/12/2015 - 12:59

A report for the synthetic biology community on a one day workshop in biomimetics at Chemistry Department. Guest post by Dr Chris Forman.

Individuals from academia and industry who are inspired by natural processes to innovate in our manufacturing, gathered from across Europe and the US for a 24 hour overnight workshop, organised by the UK based Nature Inspired Manufacturing initiative. The central idea that emerged from the workshop is that biology is a source of design solutions that can have great impact in industry.

There are two primary modes of operation for biomimetics: Top down (or pull) in which a company has a specific problem for which biologically inspired solutions are sought, or bottom up (push) in which fundamental biological research provides solutions which might be able to solve an industrial problem.

Both modes of problem solving recognise that biology has had a lot longer than humans to co-optimise physicochemical properties across many orders of hierarchy. The longevity of biological evolution gives practitioners of biomimetics a broad palette of solutions to rapidly and conveniently find novel industrial solutions with minimal effort. In both modes of operation a physical understanding is sought for an emergent biological process, allowing the resulting knowledge to be applied in alternative material contexts. Thus solutions may be implemented using completely different materials as biology. A series of examples of such solutions are included below.

The relationship between synthetic biology and biomimetics was discussed in the final panel. The key difference is that biology must manufacture its own materials that are capable of supporting any desirable new emergent properties, as well as all the properties in between. In contrast, biomimetics aims only to copy the principles encountered at the top level and has no need to fabricate the hierarchies in between. Thus synthetic biology is seen in biomimetics primarily as a provider of materials, whose sole purpose is to provide a basis for the top level behaviour that is to be emulated.

Of course within, synthetic biology the view is that a whole range of complex functionalities can be engineered into materials to perform provide functionality that is simply impossible in other contexts.

Synthesizing these view points, allows us to see that biomimetics tends to only copy a single property, whereas synthetic biology is capable of generating not only novel materials, but also multiple functionalities allowing co-evolution of functionality at distinct orders of magnitude, thus conferring, not just novel solutions, but material efficiency by solving multiple problems simultaneously.

Most of the examples in the workshop arose from copying and transferring single concepts from biology to industry:

i) technical plant stems arise from a tunable process in which synthetic polymer fibres are spun together at different angles to yield a gradient in the density of the final cylindrical pipe materials, emulating the density pattern and bending modes found in bamboo. This tunable process confers anisotropic flexibility and strength on the final product while reducing the amount of material needed.

ii) engineering creases in flat sheets, allows extremely durable and low energy switching of fins for solar regulation of a building. This was inspired by plants which have flowers that are opened by birds landing on them.

iii) Understanding joints between branches allows for flexible y connectors.

iv) Machine vision systems based on observing changes in the visual field provides enhanced image processing performance from significantly less data. The same ability of the retina to process data in-situ also inspired a new architecture for computing.

v) Synthetic biology would almost certainly be useful in the evolution of novel enzymes for the purpose of developing synthetic photosynthesis.

vi) Velcro was inspired by the seeds adhering to fabric and pet fur.

vii) Novel designs for water bottles inspired by twisting growth of trees allowed stronger designs for bottles with less material.

viii) There was a discussion about a broader challenge of inspiring entire communities to change their manufacturing methodologies to help design the cities of the future, and reduce waste.

ix) there was also a discussion on the development of a Master's degree based around the ideas of biomimetics.

This guest post was authored by Dr Chris Forman of the Department of Chemistry and the Institute for Manufacturing, who is a member of the Synthetic Biology SRI Steering Committee.

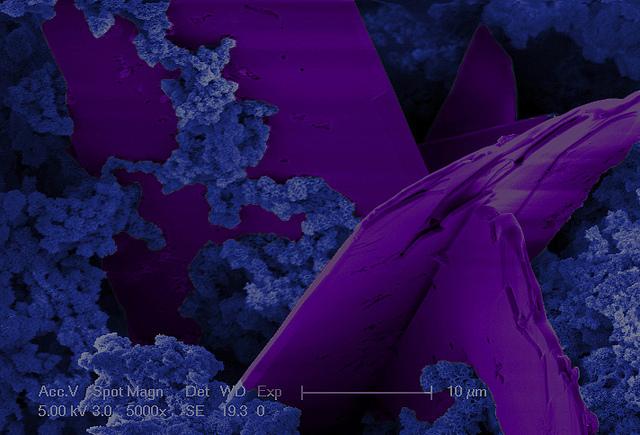

Photo by D. G. Strange from "Engineering at Cambridge" on Flickr under a CC-BY-NC-ND license.