Submitted by Administrator on Tue, 21/08/2018 - 11:27

In the developing world it’s difficult to get and maintain the hi-tech equipment we associate with modern laboratories. But could open-science hardware provide a lifeline? Rachel Brazil of PhysicsWorld investigates, highlighting several members of our synthetic biology community!

Walk into any modern physics laboratory and you’ll see all kinds of hi-tech instruments. There are spectrometers, microscopes, oscilloscopes and diffractometers all spitting out data, spectra and images. Apart from being expensive, the main problem with these “black-box” instruments is that they can’t be fully inspected or customized. If they break, you often have to pay engineers to come and fix them.

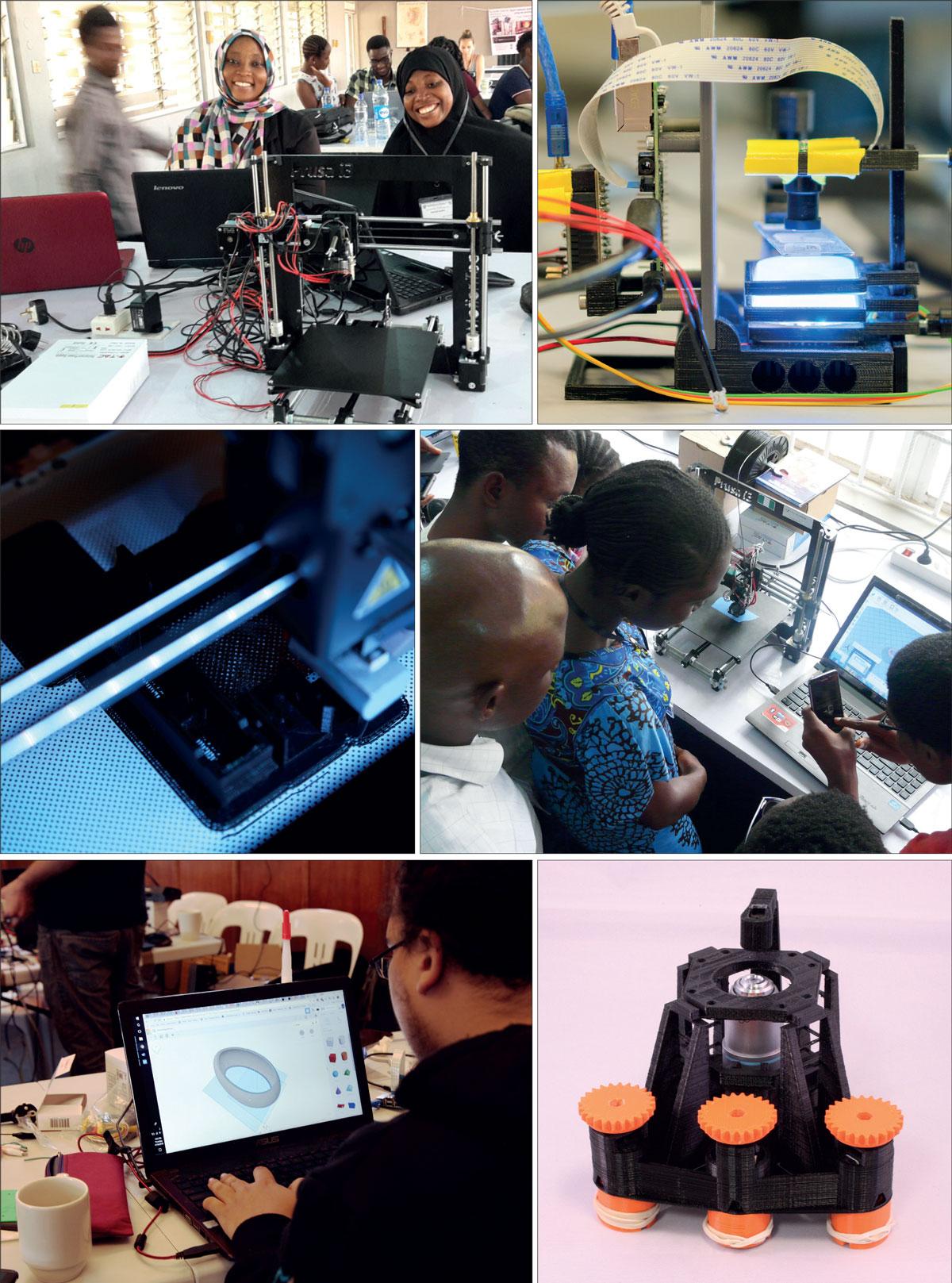

But what if you could make your own equipment? This is the principle behind the open-science hardware movement, which lets people make, modify and share hardware for scientific use. By sharing design blueprints and using 3D printers, equipment can be made quickly and cheaply. The idea has caught the imagination of many researchers, but for scientists in Africa and other parts of the developing world, open-science hardware is a lifeline that could benefit their teaching and research.

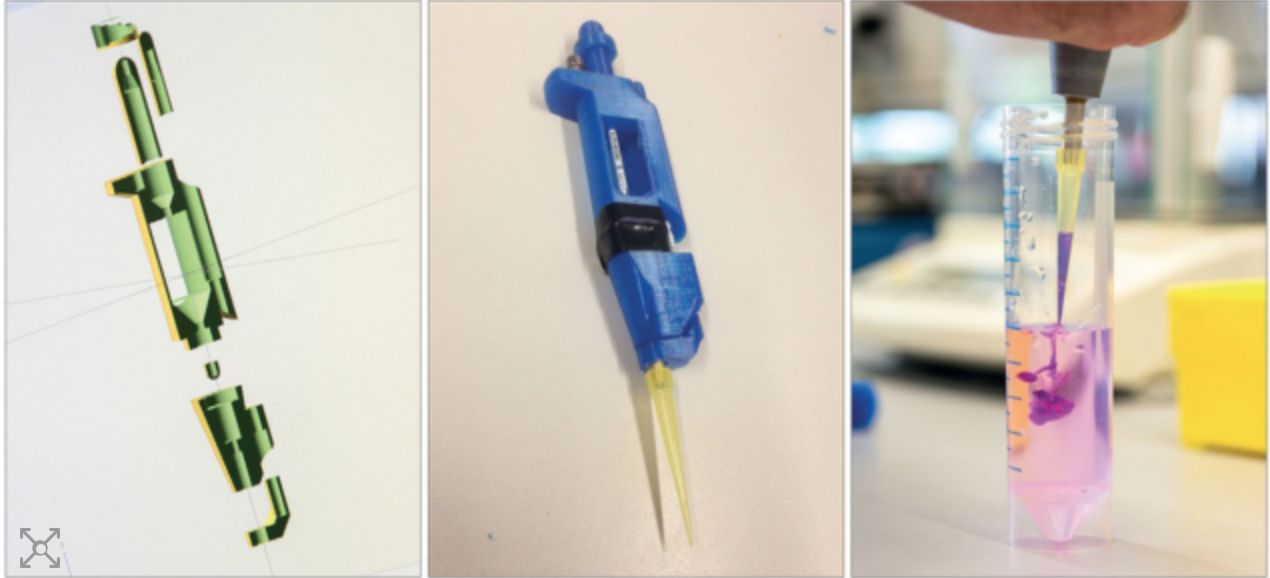

Printed pipettes: Tom Baden refined a crude design for a micropipette. (Courtesy: Open-Labware.net)

The trend for open-source hardware kicked off in the mid-2000s. It evolved from the “maker movement” in the US where DIY culture merged with hacker culture, in which members of the IT community collectively modified and developed code to improve software systems. At the core of the maker movement was the philosophy that making it easier for individuals to create things themselves could lead to a new era of micro-manufacturing and end the monopoly of mass-manufacturing. The device to enable this was the 3D printer, which was becoming cheap enough for the consumer market. People could start sharing designs thanks to online depositories such as Thingiverse, and could 3D-print them from plastic using the Lego polymer, acrylnitrile butadiene styrene (ABS), or biomass-derived polylactic acid (PLA).

The maker movement soon found its way to the sciences, but it wasn’t quite as simple as making other, non-scientific things according to Jenny Molloy, an early proponent of open science and a research fellow at the University of Cambridge, UK. “[General makers] didn’t tend to have to deal with the quality assurance, adherence to standards, calibration and reproducibility that is needed in science,” she says.

The open-source concept was not entirely new to science either. In the 1990s Linus Torvaldsat the University of Helsinki, Finland, designed the Linux operating system, which provided an underlying source code that could be used, modified and distributed by anyone. Now it’s widely used in servers, software and firmware, including Android smartphones, TiVo digital video recorders and satellite navigation systems for vehicles. Its success has often been attributed to its collaborative open-source development because it provides speedy problem solving.